About Essar Minmet Project

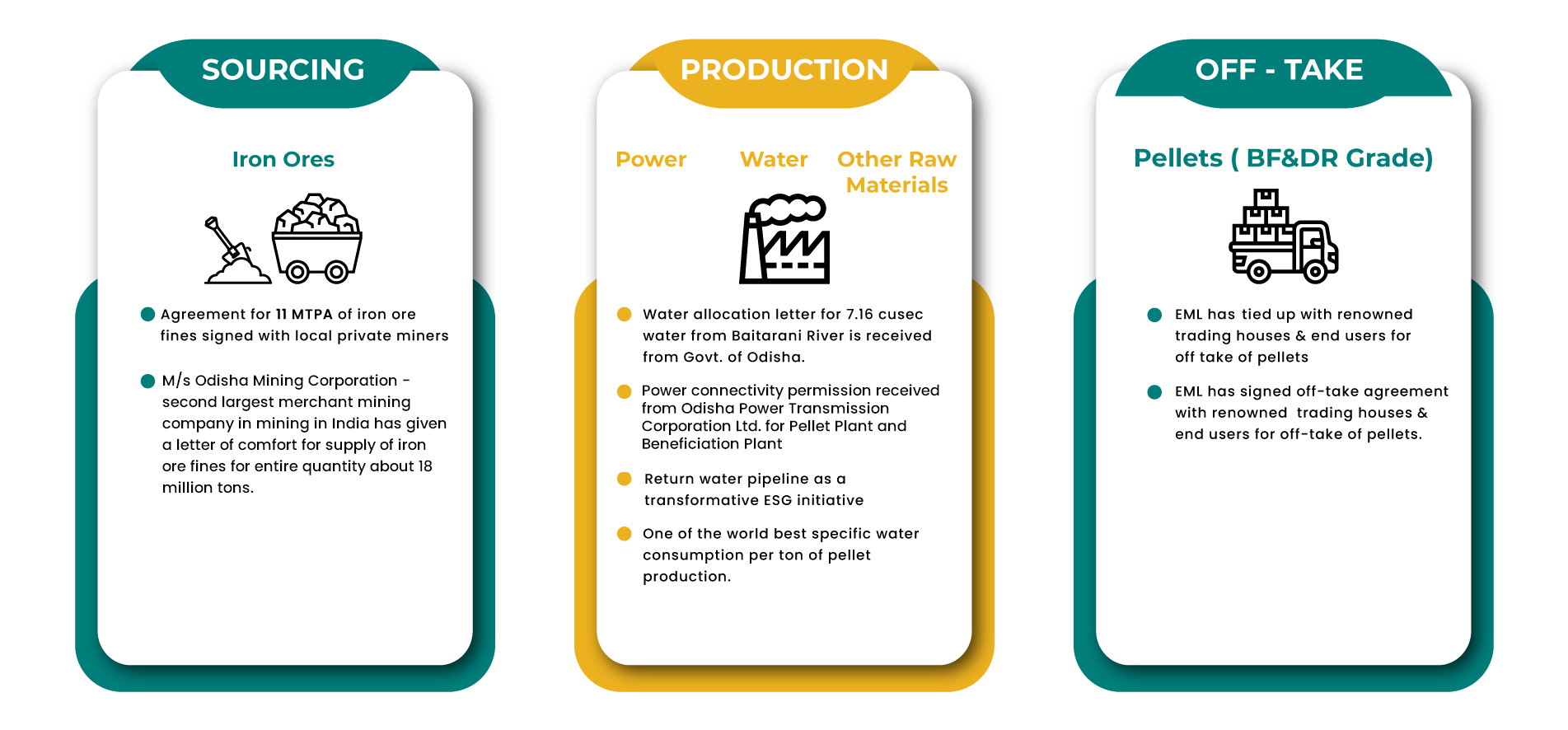

Essar Minmet is implementing 14 MTPA Greenfield Integrated Iron Ore Pelletization Project, the largest merchant pellet plant in India. Strategically located in the mineral rich state of Odisha. The project is located in the Paradip Port industrial park, with excellent connectivity to long eastern coastline, three major airports and road network.

- Only Pelletisation project in India to produce both DR&BF grade pellets at the same time.

- The entire project comes under the National Infrastructure Pipeline (NIP).